Unlocking the Secret of Non-destructive Case Analysis?

Did you know that the color (wavelength) of light emitted by glowing metals can give you a clue about their temperature? Let’s conduct a fascinating and easy-to-reproduce experiment to explore this phenomenon!

Here’s what you’ll need: an annealing setup with a ZVS-board, various cases of different calibers and head stamps, and a curious mind ready to unveil the secrets of proper annealing.

First, we’ll measure the current on the intake side of the ZVS-board at the initial stage of the annealing process (around 0.1s). This will serve as our reference point for each case.

Next, we’ll observe and measure the current when the case neck starts to glow. This is where it gets interesting! You can choose the color of glow that indicates a proper anneal for you, or if you prefer no visible glow, measure the current at the point where you believe your cases are annealed to perfection.

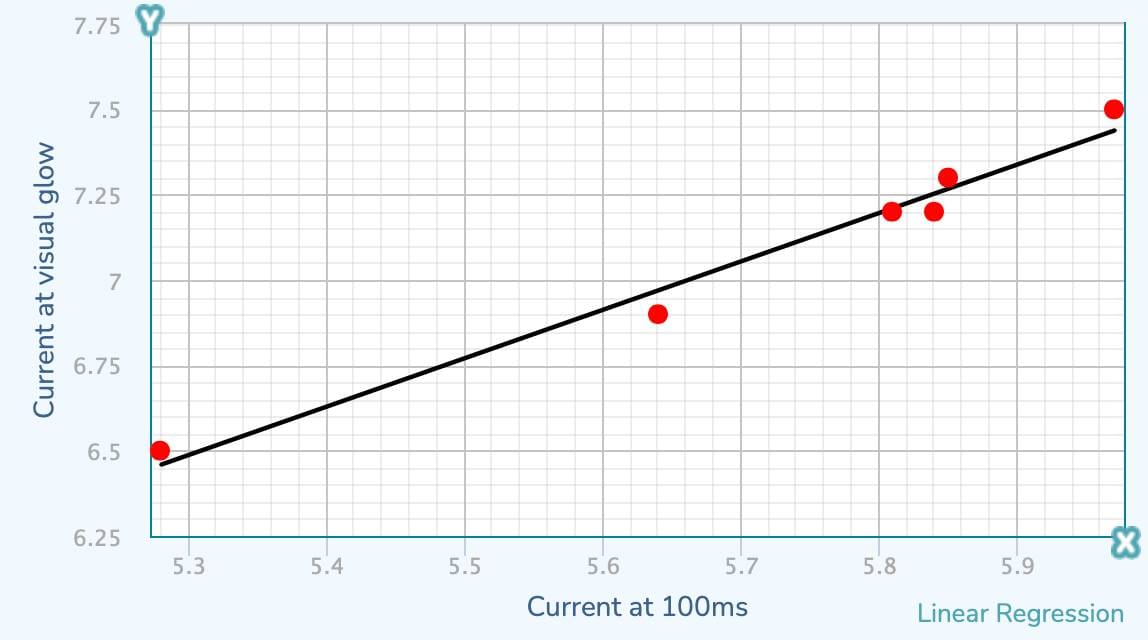

Now, let’s plot the data on a chart. The x-axis represents the current measured at 0.1s, while the y-axis represents the current measured when the glow appears. Repeat this experiment with various cases, exploring different calibers of the same head stamp and different head stamps of the same caliber.

Prepare to be amazed! When you examine the chart, you’ll notice a remarkable pattern emerging. The data strongly suggests a linear relationship between the initial current and the current measured at your desired temperature. The correlation is simply astonishing!

Now, armed with this knowledge, let’s take it a step further. By implementing a function in your microcontroller based on this linear relationship, predicting the current at which any case will glow becomes a breeze.

Just measure the current at the initial stage of the annealing cycle for a particular case, and your microcontroller will provide an accurate estimate of the current at which the desired glow temperature will be reached.

float calcGlowCurrent(float initialCurrent) {

float predicted = glowCurrentCoefficient * initialCurrent + glowCurrentConstant;

return predicted;

}

Imagine the precision and control you’ll have over your annealing process! No more guesswork or uncertainty. With this newfound understanding and the power of your microcontroller, you can achieve consistent and optimal annealing results for each and every case.